The NEW Veeder Root VersaCount 1/16 DIN size multifunction counter is the most versatile counter on the market today. Whatever your application, timing, counting, rate measuring, position indicating, volume measurement, speed monitoring, length cutting or batch, shift, pulse or piece counting, the VersaCount is the only device you need when versatility counts.

The NEW Veeder Root VersaCount 1/16 DIN size multifunction counter is the most versatile counter on the market today. Whatever your application, timing, counting, rate measuring, position indicating, volume measurement, speed monitoring, length cutting or batch, shift, pulse or piece counting, the VersaCount is the only device you need when versatility counts.

Versatility doesn’t stop with functionality. The highest count frequency in the industry enables the VersaCount to perform in applications not previously possible with an electronic counter. What would speed be without accuracy? That’s why the VersaCount features an unprecedented prescaler accuracy to one ten thousandth. Further, automation and precision control are achieved using three presets with relay hold times programmable up to ten minutes.

Versatility doesn’t stop with functionality. The highest count frequency in the industry enables the VersaCount to perform in applications not previously possible with an electronic counter. What would speed be without accuracy? That’s why the VersaCount features an unprecedented prescaler accuracy to one ten thousandth. Further, automation and precision control are achieved using three presets with relay hold times programmable up to ten minutes.

Veeder Root is the first in the industry to offer a programming assistant where applications can easily be created, archived and printed using the proprietary Programming Assistant software. VersaCount XP models allow the user to easily upload programs via USB key or Ethernet connection.

Fast input frequency up to 60 kHz allows for high speed counting and measuring applications

Up to 3 Presets for precision control (1 as absolute or trail preset, range or limit value; 2 with relay output)

Relay hold times programmable up to 10 minutes for a variety of application requirements

Prescaler adjustable from 0.0001 to 99.9999 for industry leading precision.

.

VR VesaCount Literature …

… Learn More

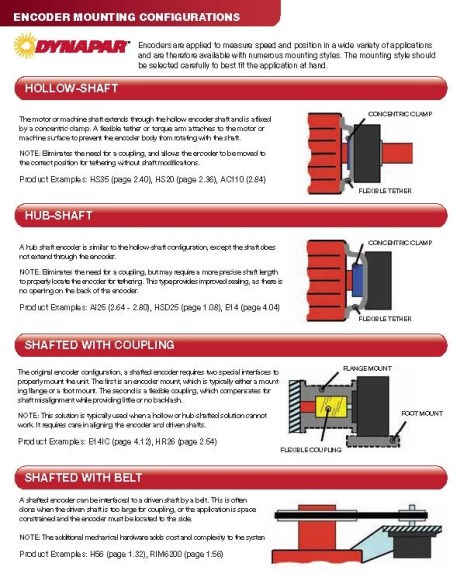

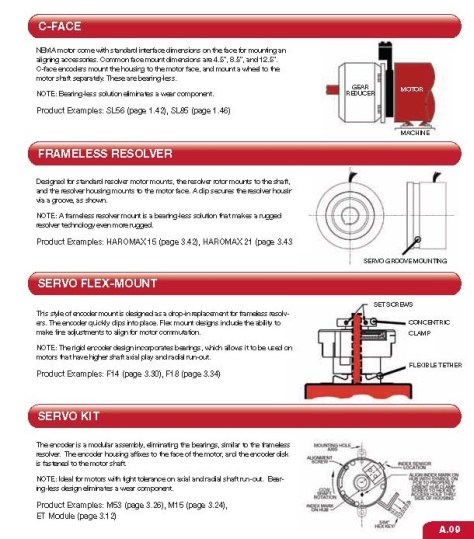

Illustrating the various method of correct Incremental Magnetic and Absolute Encoder Mounting Configurations.

Illustrating the various method of correct Incremental Magnetic and Absolute Encoder Mounting Configurations.