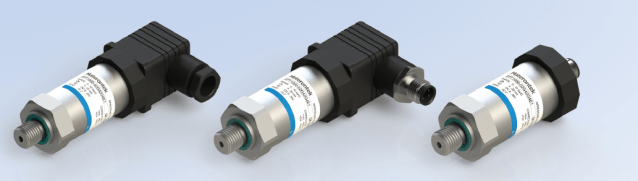

LT1000 submersible Series:

Sensing and Internet of Things

OEM Submersible Level Transmitter

Stainless steel sensor

Mass production, automated calibration

Sensing and Internet of Things

The LT1000 submersible level transmitter has been designed for level measurement in contact

With the medium in harsh operating conditions. It offers an accuracy of 0.5 %FS and with an

ingress protection of IP 68, is suitable for permanent level measurements up to 100 m water column.

Features:

- Measuring ranges from 2mH2O to 120 mH2O

- IP68, Submersible level measurement

- Low-cost, simple level measurement

- Accuracy: ±0.5%FSO(Typ.)

- Calibrated and temperature compensated

- Stainless steel pressure sensor

- Output 4…20mA, DC1…5V, DC 0.5…4.5V, MODBUS RTU

Application:

- Drinking water systems

- Ground water monitoring

- Domestic water tanks

- Rain spillway basin

Technical data

Measuring range:

Nominal pressure [mH2O] 2, 4, 5, 8, 10, 12, 15, 20, 25, 30, 40, 50, 60, 80, 100, 120

Overpressure [mH2O] 3, 6, 7, 12, 15, 20, 30, 35, 40, 50, 60, 70, 100, 110, 130

Performance:

Accuracy* 0.5 %FS@25°C *Linearity (best straight line) + Hysteresis + Repeatability

Operating Temperature -10 to 50°C

Compensated Temperature Range -10 to 50°C

Vibration 20 g RMS(20 to 2000Hz)

Shock 100 g(10ms)

Cycles 10×105

Long Term Stability 0.2 %FS

Electrical @25°C

Output signal:

- 2-wire 4…20mA / VS = 9… 30VDC

- 2-wire HART+4…20mA / VS = 12… 30VDC

- 3-wire 0.5…4.5VDC / VS = 9… 30VDC

- 3-wire 0.5…4.5VDC / VS = 5VDC

- 4-wire I2C / VS = 3.3…5VDC

- 4-wire MODBUS RTU / VS = 9…30VDC

- Insulation Resistance 100 MΩ@100VDC

- EMC Test IEC61000-6-2/IEC61000-6-3

- Reverse polarity protection No damage – no function

Physical Specifications:

- Housing 316 stainless steel

- Diaphragm 316L stainless steel

- Protection cap Stainless steel, POM-C

- Cable sheath PUR, PE, PTFE

- Oil Filling Silicone oil

- Protection IP68

- Weight ~250g (without cable)

Dimensions: (All dimensions in mm)

Features:

Features: